MGT Fiberglass Wires

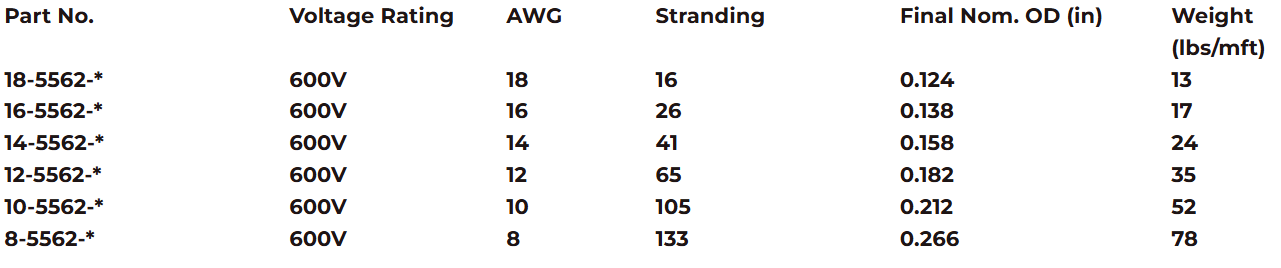

We offer a variety of TGGT (250C) and MG (450C-550C), 600V fiberglass insulated wires. TGGT cable uses 2% Nickel Coated Copper conductor and is primarily used for the internal wiring of high-temperature appliances such as dryers, heaters, and furnaces. TGGT wire is available in several Appliance Wiring Material (AWM) UL 758 styles with varying thicknesses of Teflon and fiberglass insulation depending upon the particular standard. (the most popular being UL 5256 and UL 5196).

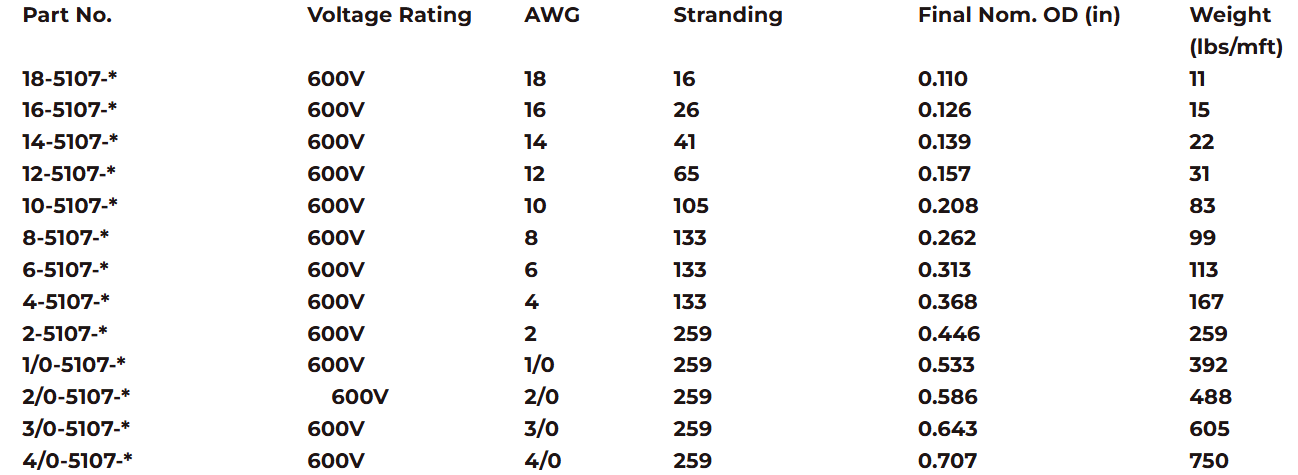

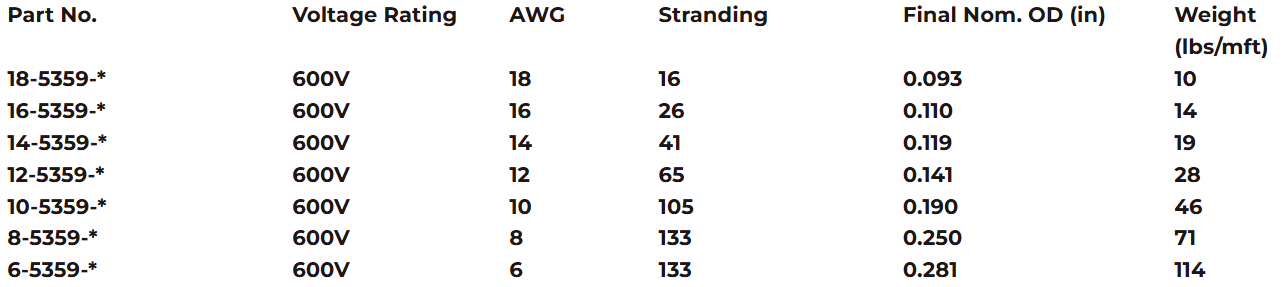

MG wires are made with 27% Nickel Coated Copper (Pure Nickel is an option) and are rated for 450C or 550C per UL. The wire features heat-resistant mica insulation and a fiberglass braid outer jacket. Popular UL Styles are UL 5107, 5359, 5128, 5400. You can use MG wire for high-temperature industrial applications like smelters, ovens, and kilns. It has excellent chemical, moisture, and abrasion resistance.

*Detailed specifications are available upon request.

Send an inquiry

Looking for MGT fiberglass wire? Search no further than CAI Wire!

Fiberglass wire (often referred to as MGT wire) is a type of electrical wire insulated with fiberglass material, which provides excellent heat resistance and durability. This fiberglass wire is designed to withstand very high temperatures, often exceeding 450°C, making it ideal for applications where other types of insulation might fail.

Fiberglass wire is commonly used in high-temperature industrial environments, such as furnaces, kilns, and ovens. It is also used in the aerospace industry, where it must sustain the harsh thermal conditions encountered in aircraft and spacecraft systems. Additionally, high-temperature fiberglass wire is utilized in the automotive industry, particularly in areas near engines and exhaust systems. In the electrical and power generation industries, fiberglass wire is often used in transformers, motors, and generators, where its heat-resistant properties are crucial for maintaining efficient and safe operation.

Here at CAI Wire we offer 450C UL/538C Factory rated MGT, as well as 550C UL fiberglass wire. Details can be found in the tables below! Please reach out to our knowledgeable staff at sales@caiwire.com for any additional information.

What is the price of MG fiberglass wire and is it worth it?

The price of fiberglass wire varies depending on several factors, including the gauge of the wire, the length of the spool, and the specific requirements of the application. Generally, the price of fiberglass wire tends to be more expensive than other types of wires used for similar purposes due to its specialized heat-resistant properties and the materials used in its construction.

Fiberglass wire’s price is influenced by its ability to withstand extremely high temperatures, which necessitates the use of high-quality fiberglass insulation. Additionally, the manufacturing process for high-temperature fiberglass wire is more complex, contributing to its higher price compared to standard wires with conventional insulation materials like PVC or rubber.

Despite its higher price, fiberglass wire offers significant benefits that justify the investment. Its superior heat resistance ensures reliable performance in high-temperature environments, reducing the risk of insulation failure and potential downtime due to overheating issues.

This durability translates to longer service life and reduced maintenance costs, making it a price-effective choice over time for critical applications. Furthermore, fiberglass wire’s resistance to chemicals, moisture, and abrasion adds to its versatility and reliability in industrial settings.

While fiberglass wire generally comes at a higher price than other wires for the same purpose, its exceptional heat resistance and durability provide substantial benefits. These advantages for the price include enhanced safety, reduced maintenance, and longer lifespan, making it a valuable investment for applications that operate in high-temperature or harsh environments.

What stands behind “fiberglass wire MGT”?

Fiberglass wire MGT (Magnesium Oxide-Glass Tape) is a specialized type of fiberglass wire that incorporates a magnesium oxide insulation layer wrapped with fiberglass tape. This design enhances its heat resistance and electrical insulation properties, making it suitable for extremely high-temperature environments, often exceeding 450°C.

MGT fiberglass insulated wire 450C is commonly used in industrial settings where high heat is a constant factor. Its typical applications include wiring for high-temperature furnaces, kilns, and ovens, as well as in heating elements and appliances that operate at elevated temperatures. Additionally, MGT fiberglass insulated wire 450C is utilized in the aerospace and automotive industries, where it must withstand the extreme conditions present in engines and exhaust systems. The MGT fiberglass insulated wire 450C is also found in power plants and other high-energy facilities where reliable performance under intense thermal stress is crucial.

The primary difference between MGT fiberglass insulated wire 450C and normal fiberglass wire lies in its construction and temperature tolerance. While standard fiberglass wire offers excellent heat resistance, MGT fiberglass insulated wire 450C additional magnesium oxide layer and fiberglass tape provide even greater protection against high temperatures, allowing it to function effectively in more extreme conditions. This added insulation layer also enhances the wire’s dielectric strength, further ensuring safety and reliability in demanding applications.

In summary, fiberglass wire MGT is designed for very high-temperature environments, featuring a unique construction with magnesium oxide insulation and fiberglass tape. Its superior heat resistance and enhanced insulation properties make it suitable for critical industrial, aerospace, and automotive applications, distinguishing it from standard fiberglass wire.

What is fiberglass wire UL 5107 and UL 5359?

Fiberglass wire UL 5107 and UL 5359 are types of high-temperature electrical wires that meet specific Underwriters Laboratories (UL) standards for safety and performance.

UL 5107 fiberglass wire is designed for use in environments where temperatures can reach up to 450°C. It typically features a stranded nickel-plated copper conductor, providing excellent electrical conductivity and resistance to oxidation. The UL 5107 fiberglass wire is insulated with a layer of fiberglass, often impregnated with a high-temperature varnish, which enhances its durability and heat resistance. UL 5107 fiberglass wire is commonly used in applications such as heating elements, furnaces, and industrial ovens, where consistent performance at high temperatures is critical.

UL 5359 fiberglass wire, on the other hand, is designed for even higher temperature applications, with a maximum operating temperature of up to 538°C. Like UL 5107, UL 5359 fiberglass wire features a nickel-plated copper conductor but includes additional insulation layers of silicone rubber, followed by a fiberglass braid. This construction provides superior thermal stability and mechanical strength. UL 5359 fiberglass wire is used in more demanding environments, such as in aerospace and high-performance industrial applications, where extreme heat and mechanical stress are prevalent.

The primary difference between UL 5107 and UL 5359 fiberglass wires lies in their temperature ratings and insulation construction. While UL 5107 is suitable for applications up to 450°C, UL 5359 is designed for even higher temperatures, up to 538°C, and includes additional insulation layers for enhanced protection.

In summary, both UL 5107 and UL 5359 fiberglass wires are engineered for high-temperature applications but cater to different levels of thermal and mechanical demands. Their adherence to UL standards ensures they provide reliable and safe performance in various industrial, heating, and aerospace applications.

Looking for quality high-temperature fiberglass wire at competitive prices? Look no further than Cai Wire! We offer a great range of high-temperature fiberglass wires at affordable prices. Contact our team today and we will send you the price list!

Fiberglass insulated wire 450C 5 - learn more

Fiberglass insulated wire 450C 5 - learn more Fiberglass insulated wire 450C 6 - learn more

Fiberglass insulated wire 450C 6 - learn more Fiberglass insulated wire 450C 7 - learn more

Fiberglass insulated wire 450C 7 - learn more Fiberglass insulated wire 450C 8 - learn more

Fiberglass insulated wire 450C 8 - learn more Fiberglass insulated wire 450C 9 - learn more

Fiberglass insulated wire 450C 9 - learn more Fiberglass wire MGT 10 - learn more

Fiberglass wire MGT 10 - learn more Fiberglass wire MGT 11 - learn more

Fiberglass wire MGT 11 - learn more Fiberglass wire MGT 12 - learn more

Fiberglass wire MGT 12 - learn more Fiberglass wire MGT 13 - learn more

Fiberglass wire MGT 13 - learn more Fiberglass wire MGT 14 - learn more

Fiberglass wire MGT 14 - learn more Fiberglass wire UL 5107 and UL 5359 15 - learn more

Fiberglass wire UL 5107 and UL 5359 15 - learn more Fiberglass wire UL 5107 and UL 5359 16 - learn more

Fiberglass wire UL 5107 and UL 5359 16 - learn more Fiberglass wire price 17 - learn more

Fiberglass wire price 17 - learn more Fiberglass wire price 18 - learn more

Fiberglass wire price 18 - learn more Fiberglass wire price 19 - learn more

Fiberglass wire price 19 - learn more Fiberglass wire price 20 - learn more

Fiberglass wire price 20 - learn more Fiberglass wire price 21 - learn more

Fiberglass wire price 21 - learn more Fiberglass wire price 22 - learn more

Fiberglass wire price 22 - learn more Fiberglass wire price 23 - learn more

Fiberglass wire price 23 - learn more Fiberglass wire price 24 - learn more

Fiberglass wire price 24 - learn more Fiberglass wire price 25 - learn more

Fiberglass wire price 25 - learn more High temperature fiberglass wire 26 - learn more

High temperature fiberglass wire 26 - learn more High temperature fiberglass wire 27 - learn more

High temperature fiberglass wire 27 - learn more High temperature fiberglass wire 28 - learn more

High temperature fiberglass wire 28 - learn more High temperature fiberglass wire 29 - learn more

High temperature fiberglass wire 29 - learn more Fiberglass wire price 30 - learn more

Fiberglass wire price 30 - learn more Fiberglass wire price 31 - learn more

Fiberglass wire price 31 - learn more Fiberglass wire price 32 - learn more

Fiberglass wire price 32 - learn more Fiberglass wire price 33 - learn more

Fiberglass wire price 33 - learn more Fiberglass wire price 34 - learn more

Fiberglass wire price 34 - learn more Fiberglass wire price 35 - learn more

Fiberglass wire price 35 - learn more Fiberglass wire price 36 - learn more

Fiberglass wire price 36 - learn more Fiberglass wire price 37 - learn more

Fiberglass wire price 37 - learn more Fiberglass wire price 38 - learn more

Fiberglass wire price 38 - learn more Fiberglass wire price 39 - learn more

Fiberglass wire price 39 - learn more Fiberglass wire price 40 - learn more

Fiberglass wire price 40 - learn more Fiberglass wire 41 - learn more

Fiberglass wire 41 - learn more Fiberglass wire 42 - learn more

Fiberglass wire 42 - learn more Fiberglass wire 43 - learn more

Fiberglass wire 43 - learn more Fiberglass wire 44 - learn more

Fiberglass wire 44 - learn more