Thermocouple Wires

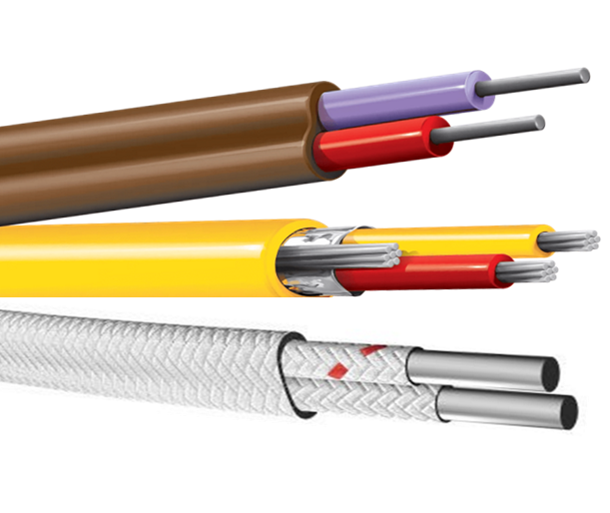

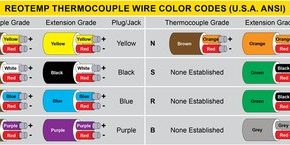

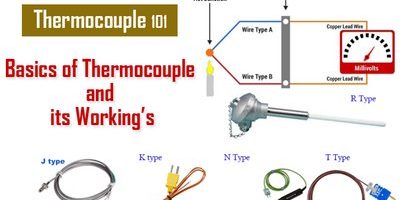

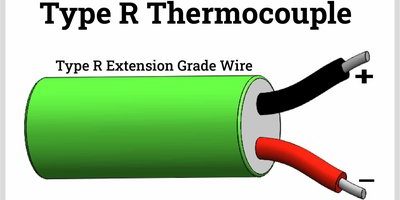

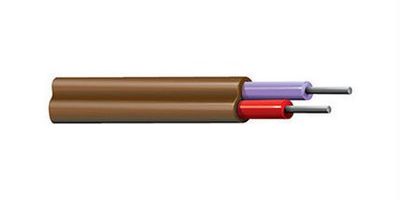

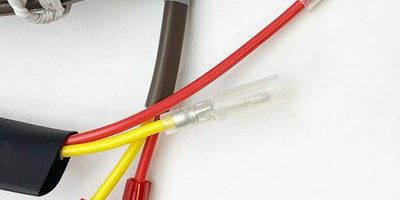

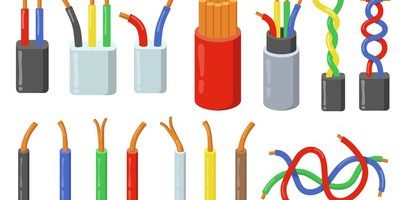

We offer a variety of thermocouple wires as well, both in thermocouple and extension grade. Different thermocouple types (most common types used are K, J, N, etc.) use different mixtures of metals in the cable. They are typically used to maintain or monitor a component’s temperature in industrial processes where high heat is present, such as kilns, gas turbine exhaust diesel engines but can be applied in safety devices, such as flame sensors in gas-powered appliances. The insulation on thermocouple wire is color coded for identification. Thermocouple grade wire is wire that is used to make the sensing point (or probe part) of the thermocouple while the extension grade wire is only used to extend a thermocouple signal from a probe back to the instrument reading the signal.

Send an inquiry

Thermocouple wire – best quality at affordable price only at Cai Wire!

A thermocouple wire is a specialized type of electrical wire used to create thermocouples, which are devices that measure temperature. These thermocouple wires are composed of two different metals or metal alloys joined at one end to form a junction. When the junction is heated or cooled, it produces a voltage that is directly related to the temperature difference between the junction and the other ends of the wires. This voltage can be measured and interpreted to determine the temperature at the junction.

Thermocouple wires are used in a wide range of applications due to their robustness, wide temperature range, and relatively low cost. They are commonly found in industrial processes where precise temperature monitoring and control are crucial, such as in manufacturing, power generation, and chemical processing. Additionally, thermocouple wires are used in scientific research, HVAC systems, automotive engines, and household appliances like ovens and water heaters. The ability of thermocouples to provide rapid response to temperature changes and their versatility in different environments make them an essential tool in many fields.

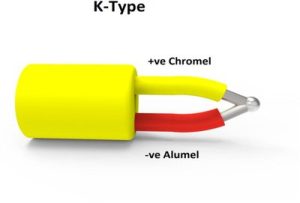

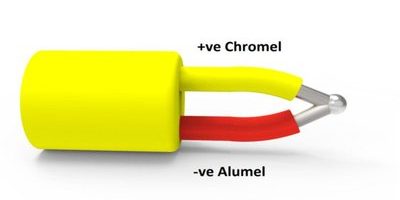

What does type K thermocouple wire mean?

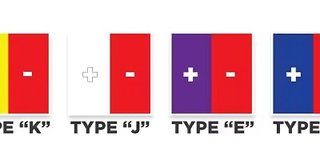

Type K thermocouple wire and extension wires refers to a specific type of thermocouple made from two metals: chromel and alumel. Chromel is an alloy composed primarily of nickel and chromium, while alumel is mainly nickel with aluminum, manganese, and silicon. Type K thermocouple wires are one of the most used types due to their wide temperature range, durability, and accuracy.

These high-temperature thermocouple wires are particularly suitable for measuring temperatures ranging from -200°C to +1260°C, making them versatile for various applications. Type K thermocouple wires are often used in industries such as metallurgy, manufacturing, and chemical processing, where high-temperature measurements are necessary. Additionally, Type K thermocouple wire and extension wires are popular in general-purpose applications, including laboratory settings and temperature monitoring in heating systems. The popularity of high-temperature Type K thermocouple wires is largely due to their reliability, resistance to oxidation, and stability in a wide range of temperatures. This makes them an essential tool in environments where precise and consistent temperature readings are crucial.

In addition to their versatility and reliability, Type K thermocouple wires are also valued for their cost-effectiveness. Type K thermocouple wires provide a good balance between performance and price, making them accessible for various applications without compromising accuracy. The construction of Type K thermocouple wires allows them to withstand harsh environments, including those with high temperatures and corrosive conditions, which further extends their usability.

Type K thermocouple wire and its extension wires are available in various configurations, including grounded, ungrounded, and exposed junctions, each offering different benefits depending on the application. Grounded junctions using Type K thermocouple wires provide faster response times and are suitable for measuring rapidly changing temperatures. Ungrounded junctions using Type K thermocouple wires offer electrical isolation, reducing interference from other equipment. Exposed junctions with Type K thermocouple wires deliver the quickest response times but are more susceptible to damage in harsh environments.

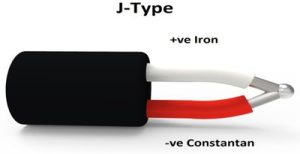

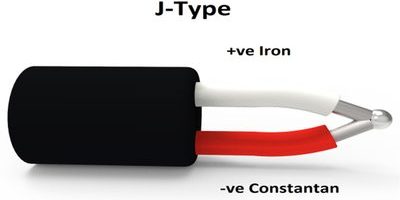

What does type J thermocouple wire mean?

Type J thermocouple wire and its extension variations is a specific type of thermocouple composed of iron and constantan, which is an alloy consisting of copper and nickel. This combination of metals allows Type J thermocouple wires to measure temperatures ranging from -210°C to +760°C. Although their temperature range is narrower compared to high-temperature Type K thermocouple wires, Type J thermocouple wires are highly accurate and stable at lower temperatures, making them suitable for a variety of applications.

Type J thermocouple wires are commonly used in industries such as plastics, food processing, and heat treating, where precise temperature control is necessary within their specific operating range. Type J thermocouple wires are particularly effective in oxidizing environments at lower temperatures, but they are not recommended for use at high temperatures or in environments with moisture or condensation, as the iron element can rust and degrade. Type J thermocouples offer a good balance between cost and performance, providing reliable temperature measurements in applications where their temperature range is adequate.

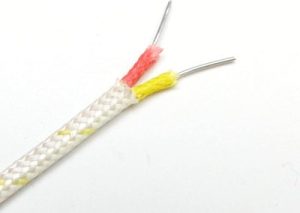

Let’s talk about shielded thermocouple wire!

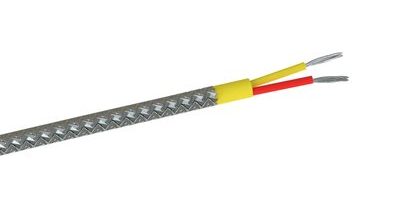

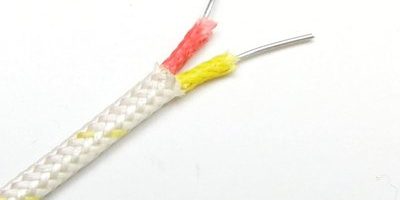

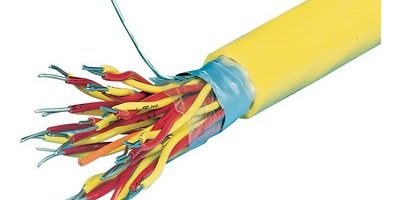

Shielded thermocouple wire and its extension variations refers to thermocouple wire that is encased in a protective shield or jacket, designed to prevent electrical interference and physical damage. This shielding typically consists of a metallic braid or foil that surrounds the ordinary and high-temperature thermocouple wires, providing a barrier against electromagnetic interference (EMI) and radio frequency interference (RFI). This is particularly important in environments where various electrical devices and machinery may cause signal noise and affect the accuracy of temperature readings.

The shielding not only protects the ordinary and high-temperature thermocouple wire from external electrical disturbances but also enhances its durability by safeguarding against physical wear and tear. This makes shielded thermocouple wires suitable for use in harsh industrial environments where they may be exposed to mechanical stress, abrasion, and corrosive elements.

Applications for shielded high-temperature thermocouple wires and extension wires include industrial process control, laboratory measurements, and any setting where precise temperature data is critical and where the environment may pose risks to unshielded wires. By ensuring accurate and reliable temperature readings, ordinary and high-temperature shielded thermocouple wires play a crucial role in maintaining process integrity and quality control across various industries.

In addition to their protective properties, shielded thermocouple wires can also help maintain the integrity of the signal over longer distances. When shielded thermocouple wires are used in large industrial setups or applications where the sensor and the measuring device are far apart, the shielding helps ensure that the temperature readings remain accurate despite the potential for signal degradation.

Shielded thermocouple wires come in different types of shielding materials and configurations, such as single shielding (a single layer of braid or foil) or double shielding (multiple layers for enhanced protection). The choice of shielding material and design of the shielded thermocouple wire depends on the specific requirements of the application, including the level of EMI/RFI present and the environmental conditions.

Looking for high-quality, high-temperature thermocouple wire and extensions? Look no further than Cai Wire! We offer a wide range of thermocouple wire – type K, type J, shielded, high-temperature, and thermocouple extension wire! Contact us for more information today!

Type k thermocouple wire 5 - learn more

Type k thermocouple wire 5 - learn more Type k thermocouple wire 6 - learn more

Type k thermocouple wire 6 - learn more Type k thermocouple wire 7 - learn more

Type k thermocouple wire 7 - learn more Type k thermocouple wire 8 - learn more

Type k thermocouple wire 8 - learn more Type k thermocouple wire 9 - learn more

Type k thermocouple wire 9 - learn more Type k thermocouple wire 10 - learn more

Type k thermocouple wire 10 - learn more Type j thermocouple wire 11 - learn more

Type j thermocouple wire 11 - learn more Type j thermocouple wire 12 - learn more

Type j thermocouple wire 12 - learn more Type j thermocouple wire 13 - learn more

Type j thermocouple wire 13 - learn more Type j thermocouple wire 14 - learn more

Type j thermocouple wire 14 - learn more Type j thermocouple wire 15 - learn more

Type j thermocouple wire 15 - learn more Thermocouple extension wire 16 - learn more

Thermocouple extension wire 16 - learn more Thermocouple extension wire 17 - learn more

Thermocouple extension wire 17 - learn more Thermocouple extension wire 18 - learn more

Thermocouple extension wire 18 - learn more Thermocouple extension wire 19 - learn more

Thermocouple extension wire 19 - learn more Thermocouple extension wire 20 - learn more

Thermocouple extension wire 20 - learn more Shielded thermocouple wire 21 - learn more

Shielded thermocouple wire 21 - learn more Shielded thermocouple wire 22 - learn more

Shielded thermocouple wire 22 - learn more Shielded thermocouple wire 23 - learn more

Shielded thermocouple wire 23 - learn more Shielded thermocouple wire 24 - learn more

Shielded thermocouple wire 24 - learn more Shielded thermocouple wire 25 - learn more

Shielded thermocouple wire 25 - learn more Shielded thermocouple wire 26 - learn more

Shielded thermocouple wire 26 - learn more High temperature thermocouple wire 27 - learn more

High temperature thermocouple wire 27 - learn more High temperature thermocouple wire 28 - learn more

High temperature thermocouple wire 28 - learn more High temperature thermocouple wire 29 - learn more

High temperature thermocouple wire 29 - learn more High temperature thermocouple wire 30 - learn more

High temperature thermocouple wire 30 - learn more High temperature thermocouple wire 31 - learn more

High temperature thermocouple wire 31 - learn more Type k thermocouple wire 32 - learn more

Type k thermocouple wire 32 - learn more Type k thermocouple wire 33 - learn more

Type k thermocouple wire 33 - learn more Type k thermocouple wire 34 - learn more

Type k thermocouple wire 34 - learn more Type k thermocouple wire 35 - learn more

Type k thermocouple wire 35 - learn more Type k thermocouple wire 36 - learn more

Type k thermocouple wire 36 - learn more Type k thermocouple wire 37 - learn more

Type k thermocouple wire 37 - learn more Type k thermocouple wire 38 - learn more

Type k thermocouple wire 38 - learn more Type k thermocouple wire 39 - learn more

Type k thermocouple wire 39 - learn more Type k thermocouple wire 40 - learn more

Type k thermocouple wire 40 - learn more Type k thermocouple wire 41 - learn more

Type k thermocouple wire 41 - learn more Type k thermocouple wire 42 - learn more

Type k thermocouple wire 42 - learn more Type k thermocouple wire 43 - learn more

Type k thermocouple wire 43 - learn more